Cold-hopped Pale Ale is straightforward, very tasty and thus popular with most beer drinkers. Because I learned how to brew this beer from my friend Herr Schmidt, and because this beer is his go-to staple beer, it is called "Schmidt's 0815". 0815 is German, meaning most common.

By the way: If this is your first beer, I recommend reading about the basics of craft beer brewing beforehand. I explain the processes in detail there.1

What is Pale Ale?

Ale is an alcoholic fermented beverage made mainly from barley malt and fermented with top-fermenting yeast at temperatures ranging from 15° to 25°C. Because of this temperature range, it is so easy to brew this type of beer at home.

Pale Ale is light to coppery in color and accented with hops, with pale referring to the color created by the use of pale malts.

INGREDIENTS

- 18l water (+ 18l water for second wort) *

- 4,5 kg Pilsener malt

- ½ kg CaraPils®

- 100 gr. sour malt *

- 100 gr. East Kent Golding pellets

(38 gr. + 62 gr.) - 1 pack Nottingham yeast (11 gr.) ***

- 50 gr. Citra® pellets **

- 6-8 gr. sugar per liter of beer

* Pale and hoppy beers, like this Pale Ale, need a low to medium water hardness of maximum 10° dH. If your tap water is harder, you can easily lower the pH value by adding 100 gr. of sour fermented malt during mashing - preferably freshly ground.

** If you can't get Citra® hops, you can replace it with Simcoe® or Cascade®.

PREPARATION

One thing up front: I like to keep the brewing process simple, which is why I mash at a constant temperature of about 68° C and don't use rests. You can read more about the rests during mashing, and why you can also skip them, in the article about craft beer.

If you don't keep a brew log yet, feel free to download my brew log template. I always take notes about the tasting on the back.

Kettle mash

Heat 18 liters of water to 74°C. I use three pots on the stove for this, and check the temperature with a thermometer with a feeler. While the water is heating, I mill the malt. You can skip this step if you bought ground malt. Since I brew more often, I store larger quantities of malt, and it keeps better if it's not ground.

For mashing in, put the malt in the brewing kettle and pour the water at 74° C, stirring constantly. Mixing with the malt causes the water temperature to drop, usually to exactly 68° C. This is the temperature that is maintained during mashing for the first 75 minutes.

After 75 minutes, the iodine test tis carried out o verify that all starch has saccharified. If the saccharification was successful, start heating up to 78° C. This will stop all processes. Please always stir well, so that there's no scorching.

The mashing process usually takes 90 minutes, starting with the mash-in and ending with a final temperature of 78°C. While the final heating is going on, you can sterilize the fermentation bucket and the other accessories (tap, lauter tray, fermentation plug, silicone hose, float, hop filter) with a boil.

Lautering, forerun and second wort

Insert the lauter tray into the lauter tun. Transfer the mash from the brewing kettle to the lauter tun using a handled mug, then simply pour over the remainder from the kettle and allow the mash to rest for 30 minutes. Meanwhile, heat the second wort (another 18 liters of water) to 75°C. Place the float in the lauter tun.

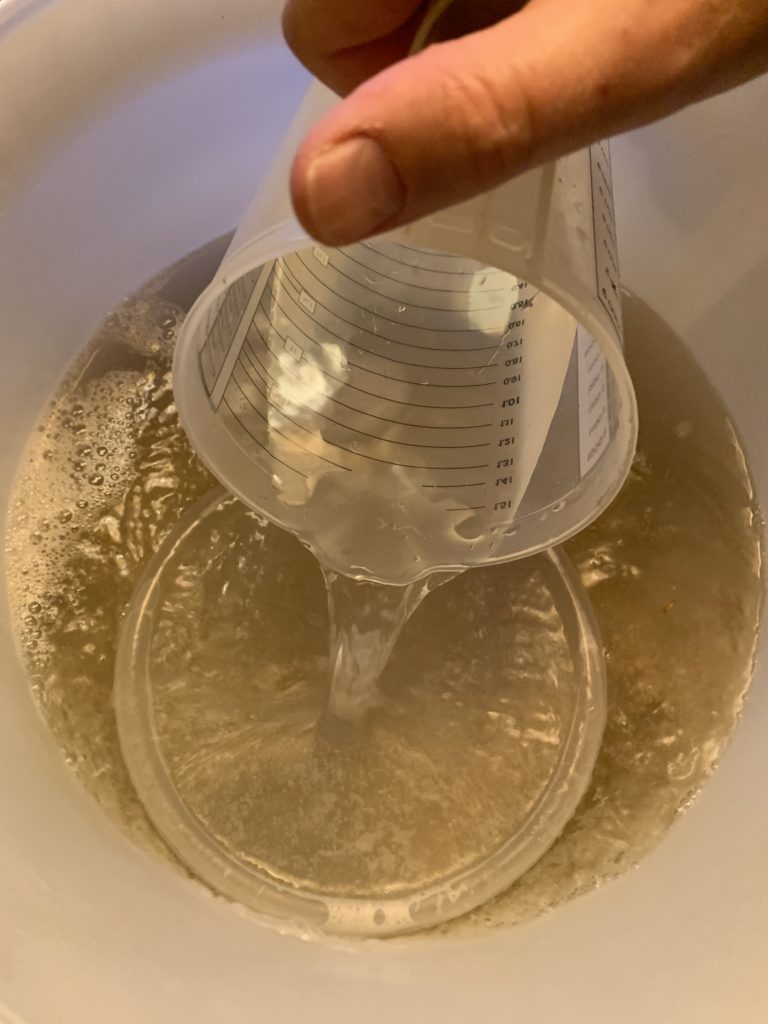

After 30 minutes, the mash is lautered. To do this, the mash is run through the tap with a silicone hose from the fermentation bucket into the brewing kettle. First, however, the mash must be clarified by the forerun, i.e. malt residues and turbidity are filtered out. To do this, you again use a mug or a large glass with which you catch the first 5-6 drained mugs and pour them back onto the float in the lauter tun. Only when the liquid that comes out is free of particles and clearer, pour the second wort on top of the float.

☞ If you do not have much experience in brewing beer yourself, you should now determine the original gravity. Why you should do this? You can read about it in the article about the basics of craft beer brewing.

Heat up and boil the wort

When the brewing kettle is filled, it is heated up to boil the wort. You can use the time until the boiling temperature is reached (just under 100° C) to calculate your hop dosage. Because once the wort is boiling, the first hop charge, the bittering hop, is added.

Calculate hop charge for Pale Ale

The best, because the simplest, overview for a wort quantity of 20 liters can be obtained from Timo. On his page Brauanleitung he also describes very clearly how to brew top-fermented beers. It's all in German, though, but the hops table should be self-explanatory and need no translation.

»Schmidt's 0815« Pale Ale is brewed with an East Kent Golding hop with ≈ 3.3% alpha acid. From Timo's hop chart2 it is apparent that 38 grams of pellets are needed for the 1st hop addition at this alpha acid value. Add the pellets to the wort, stir, and continue boiling the wort.

The second hopping is the aroma hopping. The sooner you add them, the more bitter notes will emerge. I add the 62 remaining grams from my 100-gram hop packet just before the end of the 90-minute boil. Then turn off the flame and wait for the wort to settle.

Whirlpool

For the whirlpool, the mash paddle is used to stir a vortex in the brewing vessel so that the lees form a cone in the center and are left behind during lautering. It takes about 5-10 minutes for the wort to settle after whirlpooling.

Hosing off

Now the wort is transferred from the brewing kettle to the fermentation kettle. It is important to work very cleanly here, so all the equipment must be sterile, which has been done during the boil-off at the beginning of the brewing process. If you only have one bucket, it must of course be thoroughly cleaned again after use as a lauter bucket before you can pour in the brew.

Hosing off involves filtering the wort with a strainer and gauze or cheesecloth to remove the wort breakdown and hop residue from the brew. Even easier filtering is done with a dedicated hop filter. Since these are reasonably priced, I recommend you purchase one.

Close the fermenter and let the brew cool. If I am impatient, I put the bucket in a tub of ice-cold water - normally I just wait until the next morning.

☞ Do not forget to determine the original gravity. I made a note in the brewing log.

Yeast dispensing

When the brew has cooled down to a maximum of 20° C, the yeast can be pitched. After pitching, wait 30 minutes, during which time the yeast rehydrates. Meanwhile, disinfect a ladle with boiling water. After 30 minutes, use the ladle to aerate the yeast, that is, scoop the brew and yeast several times with the ladle, draw it into the air and stir it in again.

Then close the lid tightly and let it ferment in the dark at 19° C - 22°C.

Pale Ale dry-hopping

»Schmidt's 0815« impresses with fine citrus flavors amplified by dry-hopping. The right time for this aromatization is after alcoholic fermentation is complete. To check the fermentation level, determine the plato reading every few days starting on the 5th day after yeast addition. If it does not change for 2-3 days, fermentation is complete and dry-hopping can be done.

Bottling for fermentation and carbonation

1-2 days after dry hopping, the beer is bottled. Before that, the young beer is transferred and filtered in the process.

☞ Before bottling, determine the final gravity so that you can calculate the approximate alcohol content later.

For the carbonation in bottle fermentation you calculate 6-8 gr. sugar per liter of beer. For Pale Ale, I like to use plain household sugar. You can also use dextrose, it doesn't make much difference, but you should stick to 6 gr. per liter. Dissolve the sugar in as little (about 2% of the total amount) hot water as possible. Add the sugar solution to the beer, swirl once and start bottling.

Place in a cool, dark place to age. A sealed case will help if a consistently dark place is lacking. Even small incidences of light and temperature fluctuations have a taste effect on the beer, so you should try to find a suitable place.

After 3-5 weeks your beer is ready. Taste a bottle at a time until the best taste is achieved.

The maximum shelf life is 10 months.

How much alcohol does the home-brewed Pale Ale have?

The values you need to determine the alcohol content in your finished beer are original gravity and final garvity. The difference, divided by 2, gives the approximate alcohol content in %.

1 If you brew beer in Germany, you must be registered with customs. How to do that is explained in the main article Craft Beer.

2 The table is designed for a wort quantity of 20 liters, so if you have prepared more or less, please recalculate. I have done that in this recipe for the 2nd hop addition, and then rounded a bit. Hop pellets come in 100 gr. bags, so it makes sense to use the whole bag if possible.

Sources

- brauanleitung.com, Timo Zein

- To shorten the question about my sources of supply, I have decided here for a direct link. I use exactly these supplies myself and only link to products that I know, use and appreciate. If you order your equipment through the linked recommendations, a share of the purchase price goes to me (at no extra cost to you, you know the concept under the name affiliate links). My source of supply Hopfen und mehr I would reveal to you anyway, you may already know this from my other recipes. I perceive the commission as your appreciation for my work as a writing fermentista and thank you if you trust my recommendations..